In today’s ever-evolving world, technology is helping to shape the future of nearly every industry — especially those related to construction and heavy machinery. Construction sites need robust, reliable equipment that can be used in any situation or setting. But as technology advances faster than ever before, how are these changes impacting the use of heavy equipment in construction?

In this blog post, we’ll explore some of the most significant implications for modern site management when it comes to technology and heavy equipment in the construction industry. We’ll take a look at how emerging trends such as automation and GPS tracking have revolutionized traditional processes and made them more efficient; what challenges may still exist around incorporating new technologies into operations; and finally ways that managers can maximize safety, reduce costs, plan effectively, and limit downtime through innovative use of tech on job sites.

Introducing The Inevitable Disruption Of Technology In Construction

Everything is changing. Technology has revolutionized the construction industry and brought heavy equipment suppliers to the brink of disruption. Heavy equipment in construction is being equipped with tracking technology, sensors, augmented reality glasses, 3D printing robotics, and much more. In turn, the construction process can be optimized in ways never imagined before; from monitoring productivity to reducing the costs associated with preventable accidents on site. Finally, partnering with data analysts provides invaluable insights for the overall strategy of any business – a lifting equipment supplier included.

Better yet, technology can allow for more integrated solutions that encompass the entire system: from an understanding of legal requirements and inspection reports to creating designs within tight tolerances for complex builds. While disruption is an ever-present affair, its impact on the industry may have never been greater than it is today – not just with technology but with efficiency and precision as well.

The Benefits Of Autonomous Heavy Equipment For Construction Companies

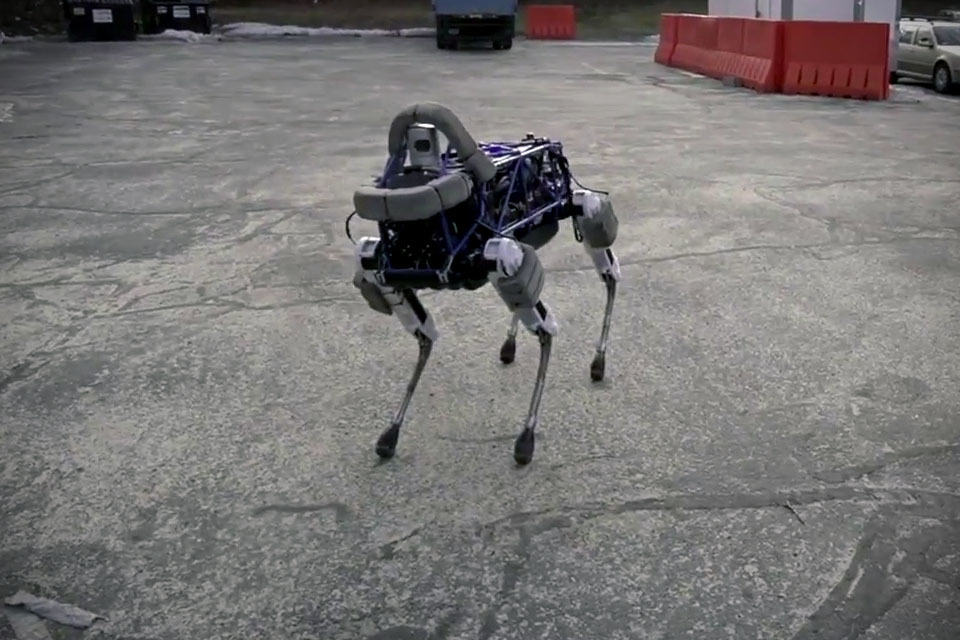

Autonomous heavy equipment is the next step in construction industry technology. By allowing self-sufficient machines to do the work, construction companies can dramatically reduce labor costs and improve safety on the job site. With automated systems, human operators don’t need to manually operate each piece of equipment—simply program it and let it take care of its tasks autonomously.

In addition, autonomous construction equipment has advanced sensors and GPS navigation that increase accuracy and detect hazards more quickly than their manual counterparts. This ensures better performance and more consistent results while freeing up employees to focus on other important tasks like customer service and project management. Autonomous heavy equipment can revolutionize the industry with increased efficiency, improved safety, and cost savings—making it a win-win choice for any construction company looking to get ahead of the competition.

Challenges And Unintended Consequences Of Using Technology In Construction

As the construction industry becomes ever more reliant on technology, its workers are increasingly presented with a series of complex new challenges in their daily tasks. Whether it’s operating heavy machinery with an unfamiliar interface, dealing with cyber-security threats, or the need for additional training that must be completed before handling technologically advanced equipment, there is no escaping the issues that come with its use. Unfortunately, these same technological advances that are intended to make our lives easier often result in increased safety risks and regulatory or legal exposures.

This means one must remain constantly vigilant to ensure that all procedures are followed correctly and any potential unintended consequences arising from the latest technology developments are managed effectively. Despite these obstacles, however, when handled intelligently and professionally, technology can provide significant value in terms of efficiency and productivity benefits to any construction site.

How To Prepare Your Business For The Onset Of Automation And Robotics

The onset of automation and robotics can be both daunting and exciting for businesses in the construction industry. To properly prepare your business, it is important to first understand what technologies are available to you, how they can be employed to make operations more efficient, and in what ways they could potentially revolutionize the way work is done. It is also a good idea to consider how automation and robotics could reduce costs or expand growth opportunities. By being proactive and preparing your business as early as you can, you will stay ahead of the curve and take advantage of the potential benefits before anyone else does.

Considerations When Choosing Automation Technology And Robotics

It’s important for decision-makers to carefully consider the various options for integrating robotic and automated technology into their workflow. Not all automation will have the same level of capability and understanding, so those choosing from among platforms need to evaluate the features that work best for their particular goals. As well, consider the operating environment; is it reliable and consistent enough to support long-term investment in automation, or will certain machines be better suited?

It’s also essential to look at scalability; can the systems support rapid growth should business opportunities present themselves, or be adjusted in some fashion if circumstances change? Ultimately, having a clear understanding of how automation can help increase efficiency while lowering costs allows organizations within the construction industry to make informed decisions when it comes to selecting and deploying automation technology.

Finally, Evaluating The Future Potential Of Technology In The Construction Industry

As technology advances and new construction projects arise, the potential of tech-driven heavy equipment applications continues to expand. Automation and robotics are increasingly seen as viable solutions that can improve construction processes, resulting in faster completion times, improved safety systems, and better quality control while reducing costs. However, these developments also bring their challenges: it’s imperative that design teams thoroughly evaluate the scope of each project before introducing new technological components. In some cases, additional machinery may be necessary to compensate for any inefficiencies caused by automation. With due diligence and robust analysis of innovation strategies, however, organizations stand to benefit from the decreased labor costs and streamlined workflows associated with tech-enabled tools in the long run.

As technology advances, the future of construction is likely to be influenced by automation, robotics, and other forms of artificial intelligence. While adopting new technology can sometimes be a challenge for traditional construction companies, it can also be immensely beneficial if done strategically. Automation has already been proven to reduce labor costs and increase safety on job sites. This is why businesses need to consider their overall long-term vision when assessing whether investing in automated business processes and robotics makes sense.

Careful analysis should be taken into account of the potential cost savings that could be gained using these technologies now and in the future. By taking all of the factors into consideration, you’ll have the best opportunity to maximize your company’s efficiency while helping protect its competitive edge within the industry. Now more than ever, construction businesses need to understand how they can use technology like automation and robotics to remain competitive, create better work environments for employees, and improve customer satisfaction to thrive in a changing world.

Featured photo by EJ Yao on Unsplash.