When Volkswagen Group’s Bugatti wowed the world with the world’s first 3D-printed Titanium Brake Caliper, we thought it will be just another fancy tech that will never see the light of production. Well, I guess I was wrong, so very wrong. As it turns out, the world’s first 3D-printed Titanium Brake Caliper is going to be made and used on actual cars after all.

As Bugatti preps its first printed titanium brake caliper for series production, this revolutionary “world’s largest 3D-printed titanium pressure functional component ever produced” was through its paces on the most powerful brake test benches.

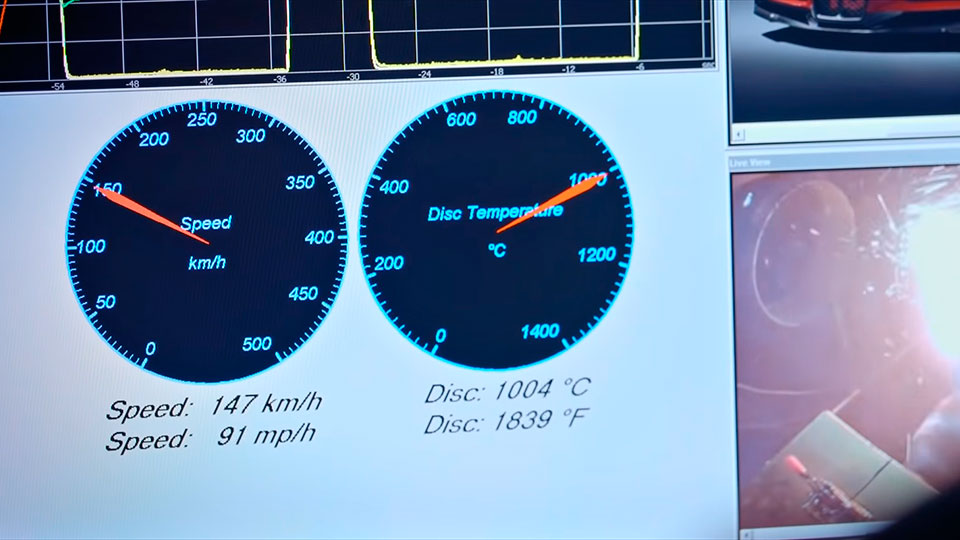

In the test, which ran for multiple times, the brake caliper was subjected to high speed run in excess of 300 km/h (186 mph) before it was made to rein in to a stop. In the process, the caliper and the brake pads were punished by extreme heat that reaches over 1,000 degrees Celsius (1,847 Fahrenheit). It was quite a sight to behold.

Sparks flew as the disc was made to grind to a halt

Check out the heat! Holy…

The “aftermath” of the grueling test

If you sense an excitement in me, well, yes, I am going ga-ga over this test (albeit it clearly being a marketing campaign). Pardon me for that silly excitement I am having. I am almost always fascinated by the immense heat and the associated orange glow resulted in braking at extreme high speed. Don’t ask why. Anyways, skip ahead for the strangely satisfying video.

Images: YouTube (Volkswagen Group).