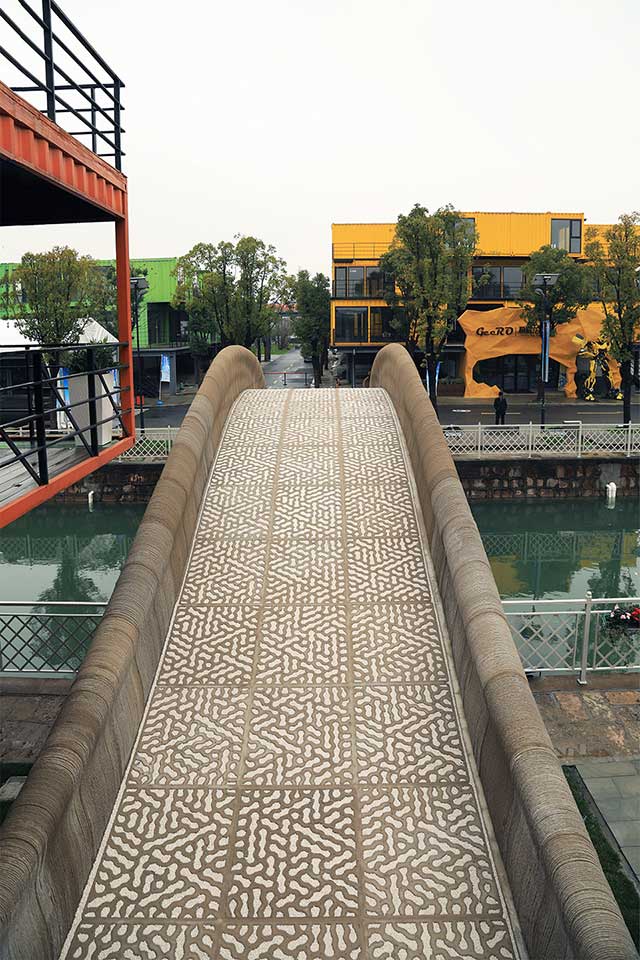

OK. It is more like the world’s longest 3D-printed pedestrian bridge, but anyways, I think you get the idea how it is groundbreaking monument in bridge construction. The bridge you see here is located at Wisdom Bay Industrial Park, Baoshan District, Shanghai, China, and it was the fruit of labor of Professor Weiguo Xu of Tsinghua University’s School of Architecture (not the Taiwan’s Tsing Hua, btw), Zoina Land Joint Research Center for Digital Architecture. The bridge was built in partnership with Shanghai Wisdom Bay Investment Management Company.

When we say 3D-printed bridge, it does not mean a giant 3D-printer was there to print the entire thing out like you do with a desktop 3D printer. That’s not the case. Instead, the components needed to construct the bridge were printed entirely by an in-house developed 3D printing concrete system. While it may sound more impressive if a giant 3D printer was there to print the entire bridge over the river, the innovations and engineering involved are no less impressive.

In fact, there’s a lot more to it, like how the printing tool of the robotic arm prevents plugging in extrusion process and collapse during stacking of the layers, and unique printing material formula developed for this purpose. There are obviously more details, but we shan’t bore you with all the geeky stuff. If you are down to learn more, you can find the details in a translated text on gooood.cn. It took two robotic arms 450 hours to complete printing all the concrete components, and cost just two-third of the cost of a similarly sized bridge built using conventional technique.

One of the reasons for this significant cost saving is, believe it or not, this bridge uses no reinforcement bars and when constructing, it requires no form work necessary if concrete pouring was used. No reinforcement bars. Lets take a moment for that to sink in. But don’t worry, this bridge, which has a structure inspired by the very old Anji Bridge in Zhaoxian, is totally capable of taking the weight of full pedestrians. Prior to the actual printing, a 1/4 scale model was created for the purpose of performing structure failure test. The test proved that the bridge is capable of taking the load.

As mentioned, the concrete aren’t regular concrete; they are composite materials composed of polyethylene fiber concrete with various admixtures that has a pressure resistance strength of 65 MPa and flexural strength of up to 15 MPa. Even so, the researchers are not going to rest on their laurels now that the bridge is completed. The bridge has real-time monitoring system embedded into it. There are vibration wire stress sensors, as well as high-precision strain monitoring system that collect the force and deformation data on the bridge in real-time.

So, yeah, the bridge is being monitored, but not for determining it will fail or not. Instead, it is to track the performance of this new concrete formula and the structural mechanical properties of the printed components. Speaking of components, this pedestrian bridge is composed of three major parts, namely, the arch structure, the handrails (more like raised sidewall or parapet, really), and the pavements. All told, the bridge boasts 44 hollow-out 3D printed concrete units, 64 handrails and 64 units of pavements. Other than the obvious engineering feat, we are totally swooned over by the organic design of this 14.4 meters (47 feet) long bridge.

Images: Tsinghua University.

Source: gooood.